The story of a startup being founded in a garage is nothing new. So worn is the cliche that many a company has fabricated their own garage story as a means of adding an underdog spirit to their origins. But for Kyle Baker, CEO and Co-Founder of Ripstop by the Roll, there is no garage story. Instead, Ripstop by the Roll's origin story is born out of his parent’s spare bedroom.

From humble beginnings this company has grown to corner the DIY market within the outdoor industry, developing and producing end-products, fabrics, and templates to feed the demand of DIY makers and fast growing companies the world over.

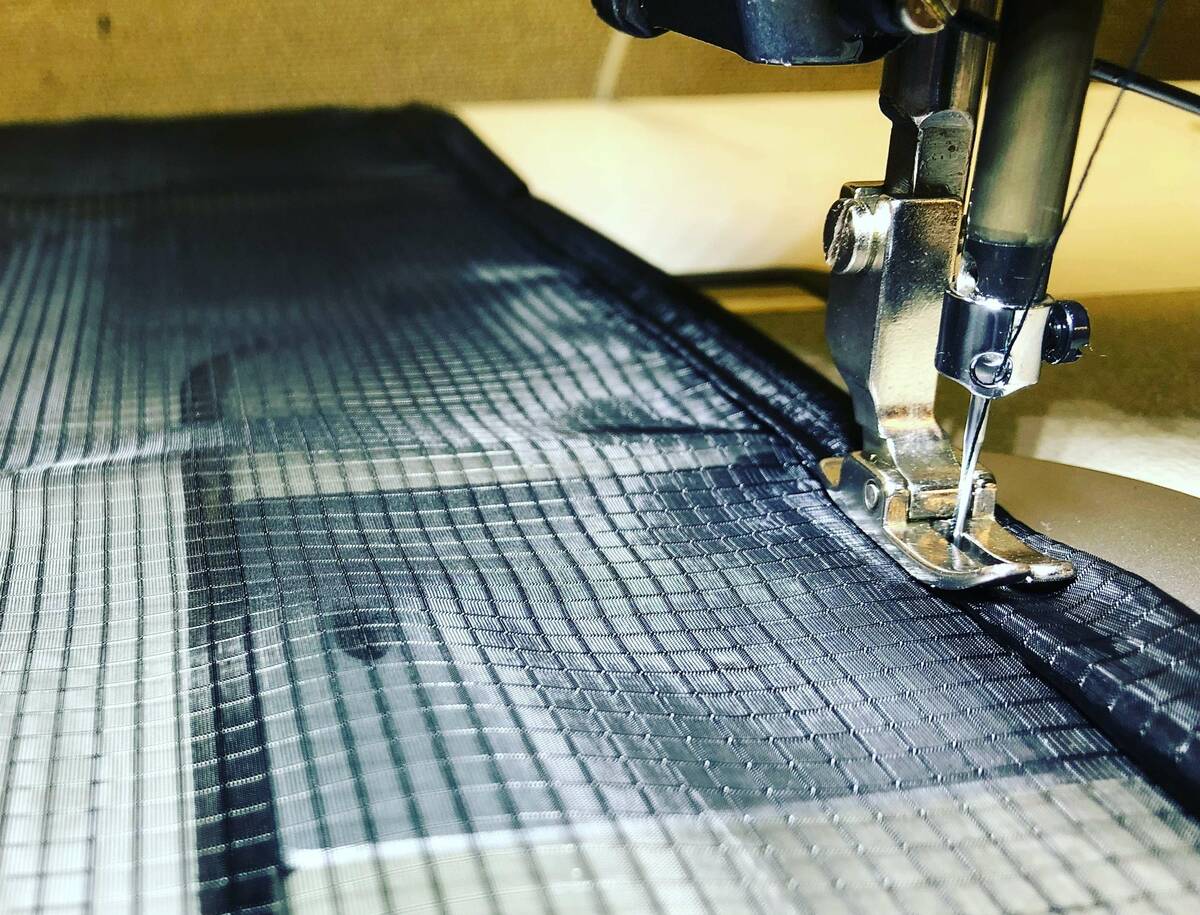

Ripstop by the Roll brings raw materials to DIY gear enthusiasts, like this 20D Ripstop Nylon mesh. If you've ever wanted to build your own gear, this is the place to start.

Camping Hammocks to Custom Fabrics

In 2011 Kyle, then 26, and his younger brother Ryan, then 14, started a small business called Appalachian Hammock, which sold camping hammocks online. Kyle, as the older brother and adult with access to capital to fund their budding empire, ran the consumer facing side of the business. Meanwhile, Ryan handled the sewing and manufacturing of the hammocks. Even though they weren’t looking to disrupt the outdoor industry, they found their hammocks had a passionate consumer base.

The two brothers quickly were overwhelmed by the number of orders they received. For anyone who has worked in a startup they’ll be familiar with the struggles that many companies go through when it comes time to scale their operations. With a staff of two, Kyle was forced to either jump in and help his brother with producing the hammocks, or let their company flounder.

“We could choose to let these orders sit there, or I could learn to sew. So it was kinda trial by fire. But I thought, if my 14 year old brother can do it, I shouldn’t be intimidated. I can do it too.”

Sewing is an integral part of any gear manufacturing, and Ripstop by the Roll's founders had to know it by heart.

The learning curve was short and steep, but soon they were off to the races. As Kyle describes it:

“I hopped on the machine and started with making a stuff sack — which is what a lot of people start with. And the first one kinda looked terrible. And the second one still looked terrible. But by the fourth or fifth one things were starting to come together. It was really cool because I’d never seen myself as a sewer. I’d built up this narrative in my head where I assumed I’d be incompetent. So it was really satisfying to see that I was wrong.”

Sewing skills verified, the brothers continued making hammocks and tarps for the small, but enthusiastic hammock camping community. Focusing on end-use products and having to source available raw materials, Kyle began to grow frustrated with what was available on the market. “We were repurposing materials that were available, but not finding exactly what we wanted in terms of how well it would perform for our usage.”

Ripstop by the Roll Is Born

As they say, frustration is the mother of invention. Subpar materials spurred Kyle to look into what would be required to manufacture fabrics from scratch; ones that would be ideally suited for use outdoors. Unfortunately the process of bringing a new product to market is rarely so simple as the desire for said product.

Almost immediately finances became an issue. As a young professional without the capital to make large scale fabric purchases Kyle needed to find a way to raise enough money to start making their own materials.

Folding fabric in the raw.

Yet they forged ahead without a master plan for international sales, without the knowledge that there was a robust community of makers clambering for affordable access to the outdoor industry’s best fabrics, like 1.9 oz Ripstop Nylon and 1.1 oz Silnylon, which were built specifically to fill voids that they saw in the market. At that time they had no idea that their company would soon outgrow factory after factory as they scrambled to fill the orders pouring in — this was the situation when Kyle launched Ripstop by the Roll.

Initially the company’s sole purpose was to sell off some of their extra fabric, the money from which would go into funding the camping hammock business. But it was not to be.

Years later Ripstop by the Roll is still in business, while the hammock company has been scrapped. As Kyle marveled, “We learned that other people were having the same issues as us in terms of finding materials. We unknowingly, fortunately, filled a niche in the market.”

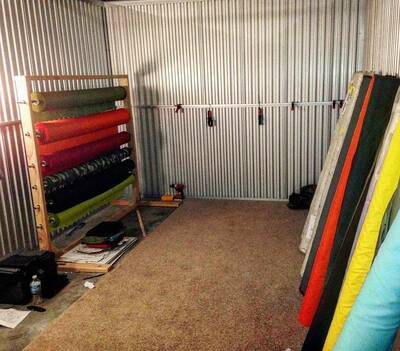

The humble beginnings of Ripstop by the Roll.

In the five years after launching Ripstop by the Roll the company enjoyed month after month of continual, organic growth. Now that they had stumbled into this niche, the DIY community was thrilled to have them. In the first nine months of operations the company scrambled to stay ahead of demand. Kyle says: “We started with everything in our parents’ bonus room. Then we moved to my basement in my apartment. Then a small and then medium size storage unit and then the biggest storage unit they had.”

With the company’s astonishing growth Kyle decided to go full in and quit his job as an electrical engineer to dedicate his time to Ripstop by the Roll. Within a year and a half Ripstop by the Roll had outgrown two fulfilment centers before finally landing in their own 12,000 square-foot factory in Durham, NC.

Dyneema Cuben Fiber being cut on the production floor of their much larger space.

Forging Ahead

Having climbed their way to the top of the DIY market, Ripstop by the Roll is careful to ensure they are continuing to listen to the passionate consumers who helped make the company viable. In discussing how they develop new fabrics Kyle says they often design their own materials from ideas born in-house. But just as often Ripstop by the Roll will respond to the DIY enthusiasts who are vocal in requesting materials they can’t find, or materials that aren’t meeting their needs.

One advancement Ripstop by the Roll has made recently is fully featured laser cutting, which seriously cuts down on time spent when building your own gear.

Listening to the community has been instrumental in Ripstop by the Roll’s continuing success. When asked about a product that embodies his company’s best offerings, Kyle is quick to point out the Laser Cut DIY kits. With kits for hammocks, shelters, accessories, bags, and even sleeping quilts, the kits offer consumers an easy way to get the materials they need. Kyle notes that “before we came along you’d have to buy a couple yards of fabric, cut it all up by hand, source the zipper and thread and put it all together yourself.” A task that sounds daunting just from the description.

This is the Netless Hammock DIY Kit, one example of buying everything you need to make a product, rather than piecing it together yourself. Of course, you can still piece it together.

However, the kits embody the Ripstop by the Roll ethos. Kyle describes it as a “win-win.” Saving the customer time, money, and hassle, while allowing the company to get creative with their laser cutter and offer a product that is in high demand and generates great revenue.

Perhaps it’s not surprising that a company born from the desire for better materials is looking to innovate outdoors fabrics once again. Ripstop by the Roll recently launched OutdoorINK, a department that’s housed within a large old-furniture showroom, but which marks an individual brand as well. OutdoorINK prints elaborate, full color patterns and designs on materials that formerly could only be found in solid, often droll, colors. These include state and national flags, nebulas, and even famous works of art.

This California Republic fabric is printed via OutdoorINK, a Ripstop by the Roll product. It's just one of many cool designs that can give some pop to your outdoor gear.

Ripstop by the Rolls’ first employee Justin Oliveri uses his degree in graphic design to create the majority of the designs for OutdoorINK. Finally, someone is injecting a much needed boost of color into the outdoor gear world.

A product that highlights each key element of Ripstop by the Roll, this DIY Roll Top Dry Bag Kit is made with DFC, using OutdoorINKs coloring book pattern. In a word? Dope.

With their meteoric rise among the DIY community and an impressive list of brand partners now sourcing their materials directly from Ripstop by the Roll, it’s safe to say that the company can look forward to a long and profitable future. By taking material design out of the grip of the big companies and putting the fabrics and resources into the hands of consumers and outdoor brands everywhere, Ripstop by the Roll has filled a niche in the industry by democratizing access to high quality, technical outdoors fabrics.

All photos used with permission from Ripstop by the Roll.

Backpackers.com Affiliate Policy: This guide contains affiliate links, which help fund our website. When you click on the links to purchase the gear we get a commission, and this goes a long way to creating guides, gear reviews, and other excellent content.

[…] Ripstop by the Roll Is Born As they say, frustration is the mother of invention. Subpar materials sp… […]